TECH TIPS – Auto Lock

Auto Lock is Kit Masters’ patented fail-safe technology that prevents on-the road fan clutch failures. It is built into every GoldTop, 2-Speed GoldTop, 8901N and 8905N fan clutch. AutoLock prevents complete fan clutch failure by locking the clutch into the fully engaged position when the friction material nears the end of its life. When this happens, the fan clutch remains in the engaged position forever, allowing replacement when convenient for the driver and mechanic.

To understand how AutoLock works, we must first understand how these fan clutches engage and disengage (All diagrams will refer to the GoldTop as an example, but Auto Lock on the 8901N and 8905N uses the same concept to operate).

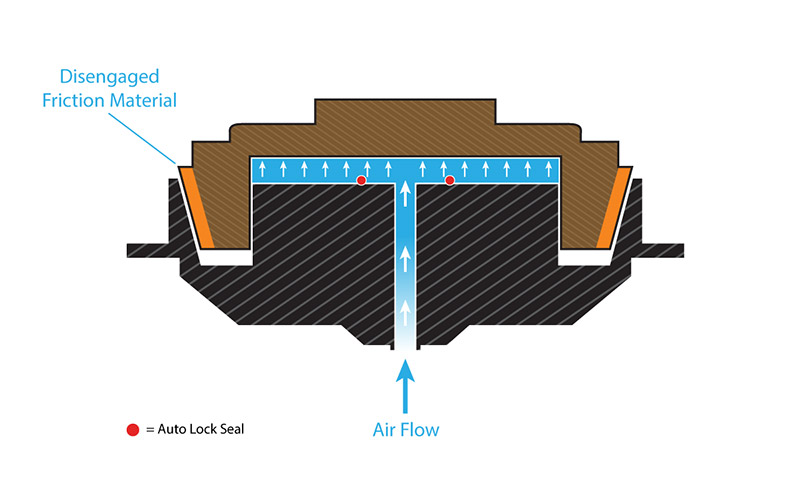

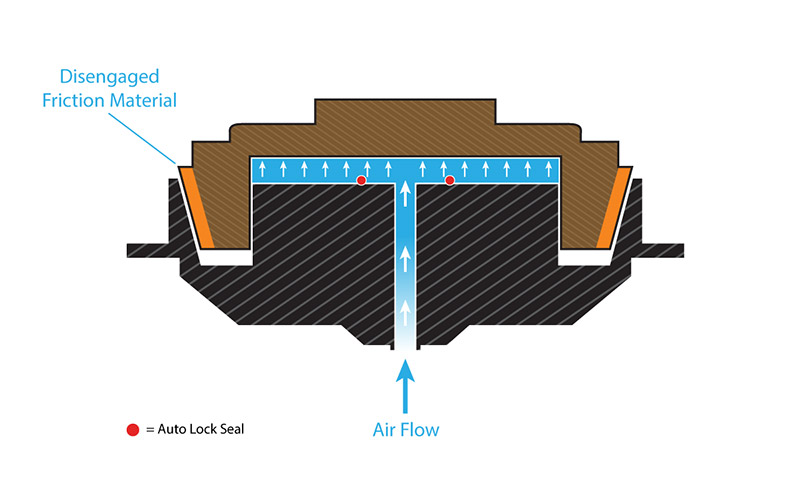

How a Fan Clutch is Disengaged:

The above picture shows the fan clutch in a disengaged position. When the engine does not need cooling, the solenoid allows air to enter the GoldTop. The force of the air pressure generated in the fan clutch is what compresses the internal spring, keeping the fan clutch disengaged. Each fan clutch requires a specific amount of air to overcome the internal spring.

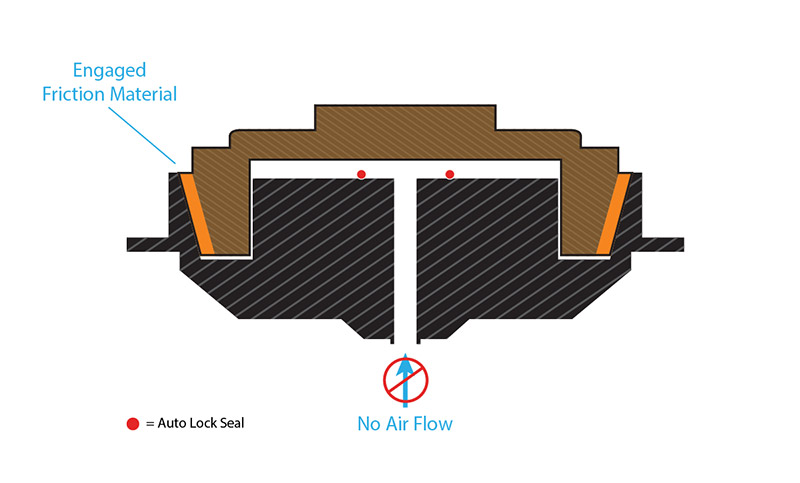

How a Fan Clutch is Engaged:

The picture above shows the fan clutch in the engaged position. Note the thickness of the friction material and the position of the top (gold section) of the fan clutch.

When the engine requires cooling, the solenoid cuts off the air supply to the fan clutch. With no air supply to overcome the spring, the spring pressure drives the friction into the bearing plate. The friction plate (which is connected to the fan) and bearing plate (which is connected to the pulley) are now locked together and turn at pulley speed.

With each engagement, the height of the friction becomes thinner and the fan plate presses further into the bearing plate.

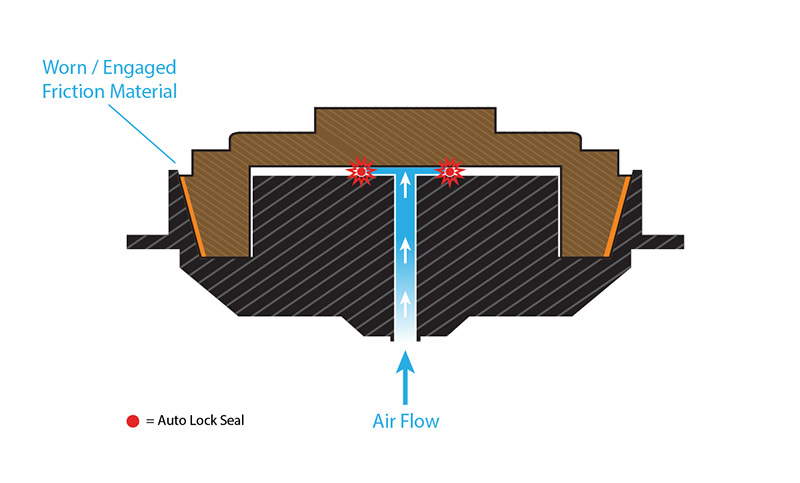

How Auto Lock Works

The above picture shows the fan clutch with Auto Lock engaged.

As the friction wears and the fan plate presses further into the bearing plate, the clearance between the fan plate and the Auto Lock seal becomes less. When the friction material nears the end of its life, the Auto Lock seal will come in contact with the fan plate. This prevents air from filling the entire air chamber. By reducing the size of the air chamber, the amount of force generated is reduced to a point where it can no longer overcome the internal spring to disengage the fan clutch. The fan clutch is now permanently engaged.

The driver may finish their route and return to the home base to have the fan clutch repaired without tow charges, using their own labor, their own timeframe and their own inventory. Most importantly, there was no downtime for the truck.