TECH TIPS – The Importance of Hub Bearings in Kysor-Style Fan Clutches

Stop me if you’ve heard this one before. Your Kysor/BorgWarner-style fan clutch has failed. You order a replacement. The replacement process is simple on these types of fan clutches. You remove six bolts, take the old fan clutch off of the hub (pulley & mounting bracket) and put the new fan clutch on in its place. Sometimes, this can even be done right on the truck without removing the entire hub. You fire up the truck and it goes on down the road. A few days later the same truck returns with a failed fan clutch. What happened? Why doesn’t your new Kysor-style fan clutch work? The most common culprit…pulley bearings.

Too often, when replacing a Kysor/BorgWarner-style fan clutch, the pulley bearings are overlooked. Many times, worn pulley bearings are what cause the fan clutch to fail in the first place. Replacing the fan clutch without replacing failed pulley bearings always results in another prematurely failed fan clutch.

When replacing or rebuilding a Kysor-style fan clutch, you should ALWAYS replace the hub bearings using the appropriate bearing kit.

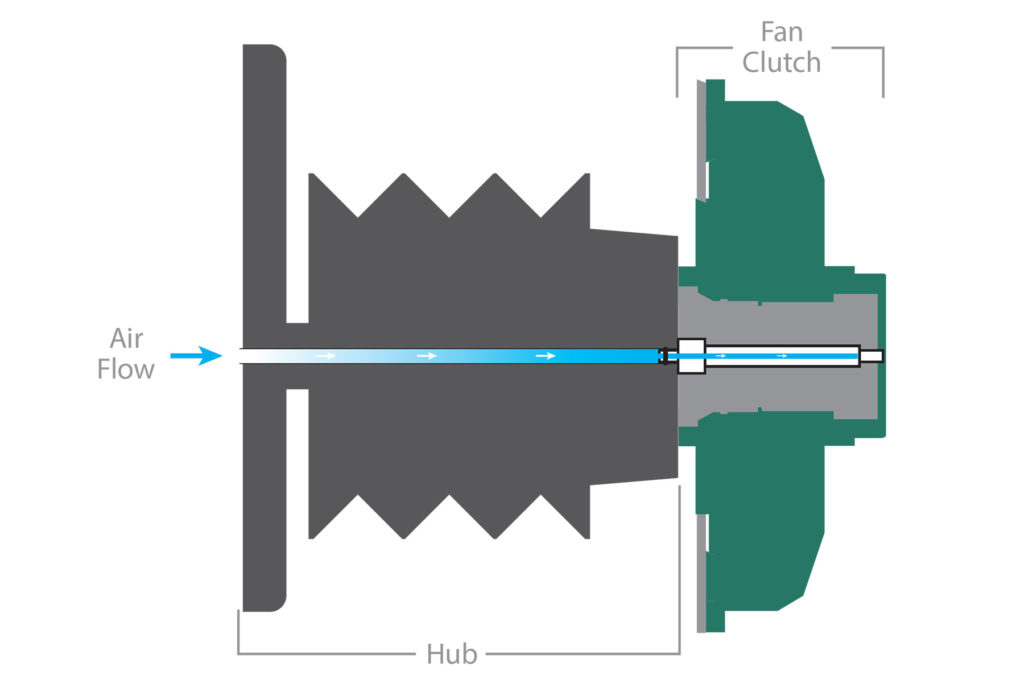

Kysor-style fan clutches consist of two components: the fan clutch and the hub (pulley & bracket). The point where the two components meet is a crucial part of this relationship. Air is transferred through the pulley shaft and into the back of the fan clutch.

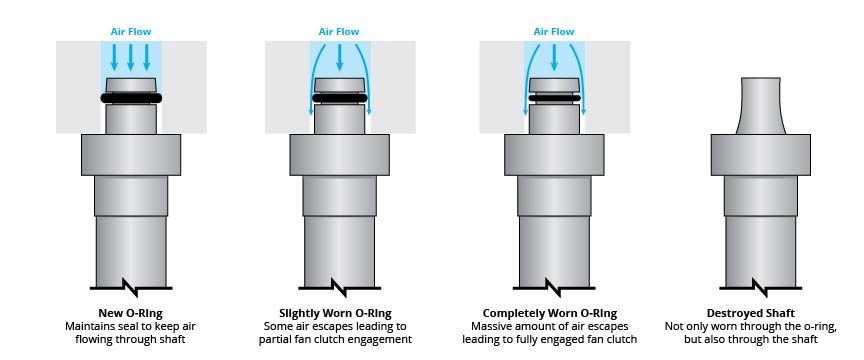

It takes at least 90psi to keep the fan clutch properly disengaged. Maintaining the proper air pressure requires a proper seal between the fan clutch shaft and the pulley shaft. This is created by a seal on the rear-air shaft. The seal ensures that all the air flow goes into the fan clutch in order to create the proper air pressure required to keep the fan clutch properly disengaged. If any air slips by this O-Ring, the fan clutch will not receive the proper air pressure and will slip on disengagement. To assist in this pairing, a black plastic coupler is installed, which serves as a guide and stabilizer.

In normal operation, there exists a very slight constant harmonic vibration due the fact that these are two components joined together with bolts. Though the vibration is very slight, it creates a slight motion on the O-Ring. The higher the RPM, the greater the vibration, and the greater the movement on the O-Ring. This motion causes the O-Ring to deteriorate over time. The greater the motion the faster the deterioration.

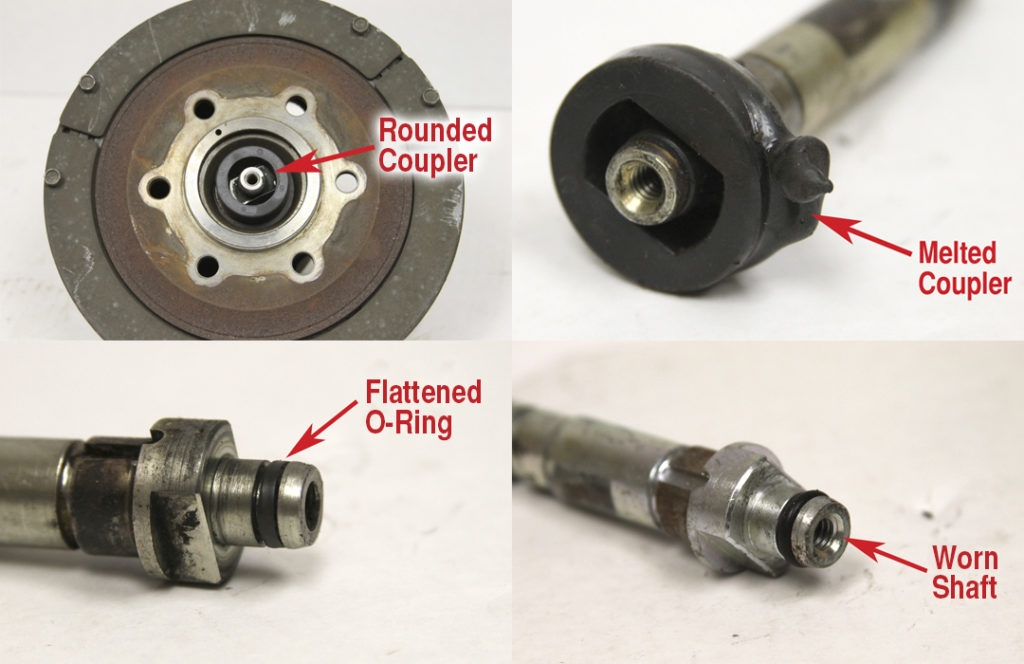

When pulley bearings begin to fail, the vibration is increased dramatically, and therefore the motion on the O-Ring is increased dramatically. This vibration causes the pulley shaft to damage the o-ring(s) on the fan clutch shaft, the black plastic coupler and even the fan clutch shaft itself. This damage leads to air leaks, which in turn prevent the fan clutch from having enough air pressure to fully disengage. A partially disengaged fan clutch will slip which causes an immense amount of heat and the fan clutch will fail.

This entire chain reaction is caused by worn pulley bearings, but all too often the attempt to fix it is shortsighted because the installer is only replacing the fan clutch. When you only replace the fan clutch, you are putting a new clutch with a new O-Ring into a high vibration environment, which will always cause premature failure. To do a proper job, you must replace the fan clutch AND the pulley bearings every time. Doing this will help to ensure that you fix it right the first time, every time.